In the evolving landscape of Science, Technology, Engineering, and Mathematics (STEM), additive manufacturing emerges as a revolutionary force, transforming ideas into tangible realities. This blog post delves into additive manufacturing principles and their profound significance in modern design and engineering. It offers insights for students, teachers, educators, and mothers who play pivotal roles in nurturing the next generation of innovators.

What is Additive Manufacturing?

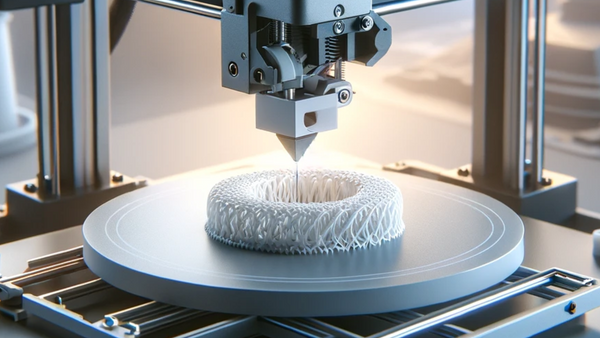

Additive manufacturing, commonly known as 3D printing, creates three-dimensional objects by adding material layer by layer based on digital models. Unlike traditional subtractive manufacturing methods, which remove material to create shapes, additive manufacturing builds objects directly from computer-aided design (CAD) files, offering unparalleled flexibility and efficiency in design and production.

The Principles of Additive Manufacturing

At its core, additive manufacturing involves three basic steps: design, division, and printing. First, a detailed digital model using CAD software allows designers to create an exact digital model. This model is then sliced into thin, horizontal cross-sections by specialized software, translating complex designs into a language understandable by 3D printers. Finally, the printer constructs the object layer by layer, using materials ranging from plastics to metals and even living cells in bio printing applications.

Significance in Modern Design and Engineering

Additive manufacturing stands at the forefront of innovation in STEM, bridging the gap between imaginative design and practical functionality. It enables engineers and designers to:

- Prototype Rapidly: Quickly turn concepts into prototypes, allowing for faster iteration and innovation.

- Create Complex Geometries: Produce parts with complex internal structures that are impossible to make with traditional methods.

- Customize and Personalize: Tailor products to specific needs or personal preferences, which is crucial in medical implants and educational tools.

Application in STEM Projects: Wind Turbines

Additive manufacturing has many applications in science, technology, engineering, and mathematics (STEM) and is especially useful for designing and prototyping new products. For example, engineers can use 3D printing to create custom parts for wind turbines that are more efficient and use less energy. Students can also learn about renewable energy by building miniature wind turbines using 3D printing.

Empowering the Next Generation

For educators and parents, additive manufacturing offers a powerful tool to inspire creativity and innovation in young minds. Here's how:

- Integrating Technology in Education: Incorporate 3D printing projects in STEM curricula to give students a tangible understanding of abstract concepts.

- Encouraging Problem-Solving: Challenge students to design solutions for real-world problems, fostering critical thinking and engineering skills.

- Cultivating Creativity: Allow students to express their creativity by creating 3D models and blending art and technology.

Conclusion

Additive manufacturing is not just about creating objects; it's about unleashing potential and turning imagination into innovation. It is crucial in advancing STEM education and empowering future generations by bridging the gap between design and functionality. For students, teachers, educators, and mothers committed to nurturing curiosity and creativity, understanding and embracing additive manufacturing is a step toward building a future where ideas know no bounds.

As we continue to explore the capabilities of additive manufacturing, let's assume the opportunities it presents for learning, teaching, and innovating in the STEM field. Whether you're experimenting with designs at home, introducing new projects in the classroom, or simply curious about the future of technology, Additive manufacturing opens up a world of possibilities waiting for discovery.